INTRODUCTION

The world is facing devastation caused by plastic waste. Approximately 60% of 80,000 metric tonnes of plastic ever made is no longer in use by humankind and is instead either utilized as landfill or is released into the environment. If calculated on the basis of contribution per individual living on the planet, it amounts to about 400 kg1. Once plastic materials are discarded into the environment, they end up in landfills or oceans because degrading them at ambient temperatures is difficult and they require decades to decompose. Hence, reduction, reuse and recycling are the three pillars of sustainable development that can help save the environment.

Traditional physical or mechanical recycling typically grinds down plastic into smaller components that are then mixed and molded to create low-grade plastic products. Even though the concept of chemical recycling of plastic waste has been known since decades, it has started to receive much attention only recently. Chemical recycling breaks down the plastic to molecular levels, thus facilitating the buildup of new materials based on the molecules that have the potential for a wide range of applications. The plastics are depolymerized to their respective monomers or oligomers. Several types of chemical treatment methods have been developed to deal with different types of commercial plastics[1].

TYPES OF PLASTIC MATERIALS

Polyolefin based plastic materials, such as those based on linear density polyethylene (LDPE), high density polyethylene (HDPE), linear low-density polyethylene (LLDPE), polystyrene based, acrylate based-such as PMMA, polyurethane, and polyester are considered for chemical recycling.

TYPES OF METHODS FOR CHEMICAL RECYCLING

Various types of chemical recycling methods are available, based on the type of plastic waste material used. These include methods such as gasification, pyrolysis, solvolysis, supercritical fluid, depolymerization and microbial, wherein the plastic waste is broken down into monomers, the chemical building blocks, for the production of new plastic materials. However, problems exist with plastic materials such as single use plastics, multi-layer laminated plastics etc. which are difficult-to-recycle. This paper brings out the successful research efforts of select leading companies.

RECENT DEVELOPMENTS

Plas-TCat chemical recycling technology from Anellotech uses a one-step zeolite catalyst-based process for the conversion of single-use plastics directly into basic chemicals, which are, in turn, used to make new plastics. The new process can be switched between two different production modes such as Hi-Olefins, which results in the production of olefins, or Hi-BTX, which produces mostly aromatics such as BTX and para-xylene.

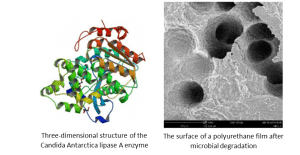

Researchers working on the EU-funded ENZPLAST2 have developed a recycling technology that degrades the middle adhesive layers of multilayer materials. This facilitates the easy recovery and recycling of other layers. This new technology is based on the isolation of microorganisms that are capable of biodegrading specific types of polymers. Biodegradation of plastics involves two steps:

- Binding of microorganisms to the polymer surface and

- Growing of the microorganisms using the polymer as a source of carbon.

This is followed by polymer degradation into CO2 and water under aerobic conditions, and biogas and water under anaerobic conditions.