INTRODUCTION

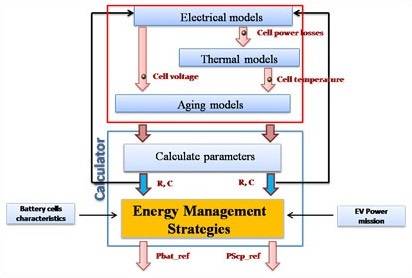

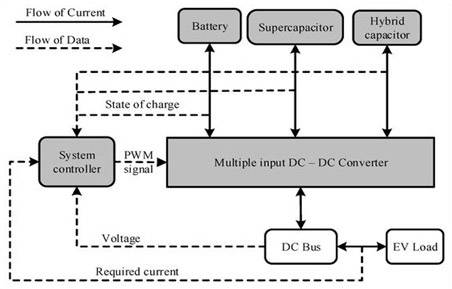

Batteries are used as energy storage devices in multiple applications. However, batteries have certain disadvantages, such as low power density, limited life cycle and comparatively slow response in the context of certain applications. The feasibility of using a battery may be limited when dealing with transient high-power demands, such as the output power and load variability from transient renewable energy sources (RES). This may lead to an oversized design of batteries, resulting in increased investment cost and additional power loss due to the slow response of the batteries while compensating for transient peak power demands.[1]

Electric vehicle (EV) batteries are particularly prone to degradation due to high peak power and harsh charging/discharging cycles during acceleration and deceleration. Moreover, battery-powered electric vehicle (BEV) applications require high power, resulting in an oversized battery pack and less optimal use of energy.[2]

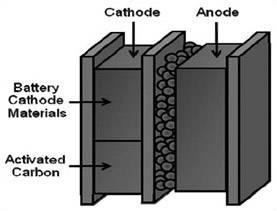

Supercapacitors (SC), on the other hand, do not store as much energy as batteries; and have the ability to accumulate and release the energy very rapidly. These devices are suitable for high power vehicle applications, for providing power that is required to accelerate the vehicle or recover the available energy during braking phase. Supercapacitors cannot be used as the sole power source for EVs, as they have low energy density compared to batteries. However, they provide good options to compensate for the high peak of usage during short periods of time when battery power is not sufficient.[3]

Battery-Supercapacitor Hybrid Energy Storage System (HESS)

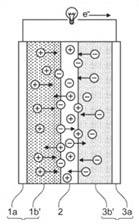

Battery-supercapacitor hybridization helps overcome the limitations of batteries or supercapacitors. It reduces the stresses applied to batteries, thus improving their life.[4]

The hybridization of the embedded energy storage systems provides the following advantages:[4],[5]

- Improved Li-ion battery lifetime

- Maximized energy recovery during braking

- Reduced size of embedded energy storage system

- Reduced cost of embedded source

Battery-Supercapacitor Hybrid Energy Storage Systems in Electric Vehicles

Electrification is an important means of decreasing greenhouse gas emissions in the transportation sector. The global electric car fleet has now exceeded 5 million and will continue to increase in future. The energy storage system is a critical part of the electric vehicle. The storage system has to be cost-effective, light, efficient, safe, reliable, occupy less space and have a long life. It should also be produced and disposed of in an eco-friendly way.[6][7] Interestingly, electric vehicles can be used as back-up storage during periods of grid failure or spikes in demand. Elverlingsen in Germany collects almost 2,000 batteries from Mercedes Benz EVs to create a stationary grid-sized battery that can hold 9 MW of energy.[8]

The lithium-ion (Li-ion) battery technology plays a major role in EVs due to its power and energy density. Supercapacitors (SC) possess extremely high-power density, high cycle time, cycling efficiency and low energy density. Connecting battery pack with supercapacitors is considered to be an effective method to provide energy and power for EVs and Hybrid Electric Vehicles (HEVs) as it results in both high power and high energy capability.[9][10][11]

RECENT DEVELOPMENTS

CRE Technologies has developed a hybrid supercapacitor battery that is useful for memory backup, energy storage for short-term operation, power for long-term operation and instantaneous power, for applications that require relatively high current units up to several hundreds of amperes.[12]