Abstract:

Disposal of used Absorbent Hygiene Products (AHPs) is a critical ecological problem assuming serious proportions. Increase in waste created by diapers, leading to increased awareness, has forced manufacturing companies to provide sustainable solutions. Technologies are being developed to recycle almost all parts of diapers. Diaper manufacturers seem to be collaborating with partners to overcome multiple challenges in this area. Recycling of AHPs requires great co-ordination between different partners, right from suppliers of materials to manufacturers, waste collectors and recycling partners, though it will certain contribute to a circular economy.

Introduction

Disposal of used Absorbent Hygiene Products (AHPs) is a critical ecological problem that is assuming serious proportions. With increasing awareness about sustainability and circular economy among corporates and the consumers, recycling of AHPs has gained universal attention. Recycling of AHPs requires great co-ordination between different partners, right from suppliers of materials to manufacturers, waste collectors and recycling partners.

According to the European Disposables and Nonwovens Association’s (EDANA) sustainability report for 2019, the targets fixed for AHP wastes include reduced use of raw materials, development of new recycling and upcycling technologies. These are high on the agenda of the nonwovens value chain for producers, converters and suppliers alike[1]. In recent years, some innovative techniques that are ready for commercial operations in EU Member States have been developed.

Current challenges in disposal

- Used absorbent products contain organic excretions and bacteria, and also have a high content of humidity, causing undesirable odor. It is therefore necessary to carry out a sterilization process before recycling of the materials.

- Diapers contain significant number of materials derived from petrochemicals (fibrous layers, top sheet components, core wrap components, cuffs, liquid barrier components, and Super Absorbent Polymers (SAP)), which are neither environment friendly nor recyclable.

- Separating the materials such as plastic, cellulose fibers and SAPs is a difficult and cumbersome process because they are intimately interconnected and it would be necessary to carry out a complete destruction of the products.

- Absorbent articles are thrown away in a folded condition, due to which the outer impermeable layer prevents effective sterilization. The articles therefore need to be shredded before undergoing a recycling process.

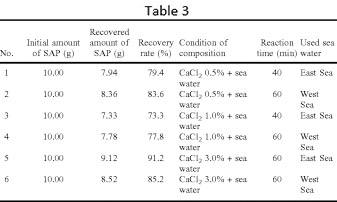

- A large amount of water is required for washing, and the wash water containing a number of pollutants, such as jellified superabsorbent polymers and organic residues, poses problems during waste water disposal[2].

- Drying of wash water consumes a high amount of energy.