Introduction

The automobile industry has been constantly pushing towards enhancing automobile features to meet increasing mileage and emission requirements. This is being approached through the use of innovative materials and manufacturing processes. The major approaches towards achieving these objectives include reducing aspects such as aerodynamic drag, driveline and transmission losses, tire rolling resistance, and electrical parasitic and vehicle weight. Among these, reducing vehicle weight seems to be the most cost-effective. OEMs are now gearing up towards light-weighting a vehicle in order to increase performance and efficiency while decreasing emissions and maintaining safety and comfort. Global efforts towards CO2 reduction and fuel optimization have given impetus to the current concept of Lightweight Vehicles.

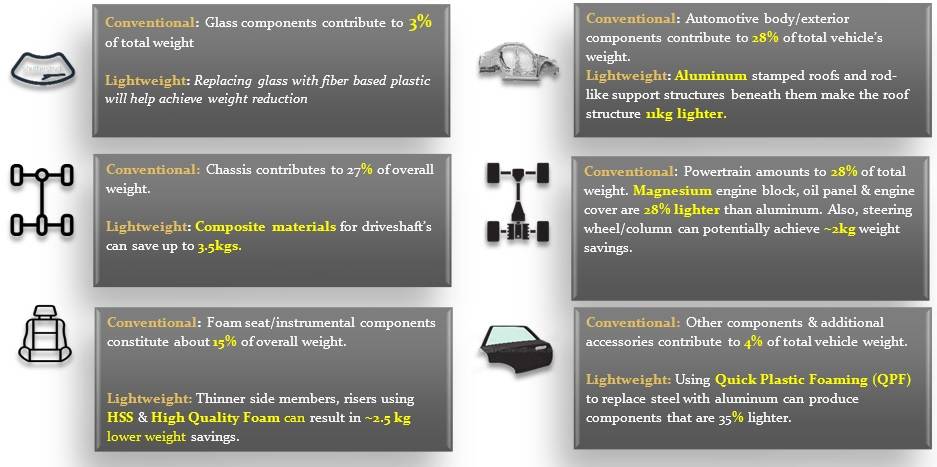

For an average automobile, the weight contributed by individual components such as chassis, powertrain, body and other exterior components is approximately 80% of the total weight. Hence, most of the automakers and OEMs are focusing on such components to achieve overall weight reduction. Studies are being conducted to identify materials that can solve the critical issue of component weight. According to information sources, approximately 10% reduction of vehicle weight contributes to 6-8 % reduction in fuel consumption and 5-6% in emission volume reduction. Though not a huge number, in the growing competitive market, these figures can hugely add to the OEM’s market promotions.